There are mainly four types of leather if we exclude faux leather. Leather is divided into these types based on grades, the lowest graded, hence the lowest quality leather is known as bonded or reconstituted leather. Among the masses, confusion is found regarding what bonded leather really is, and how it differentiates from other kinds of leather. When talking about bonded leather one can say that it is not entirely natural, but an engineered product.

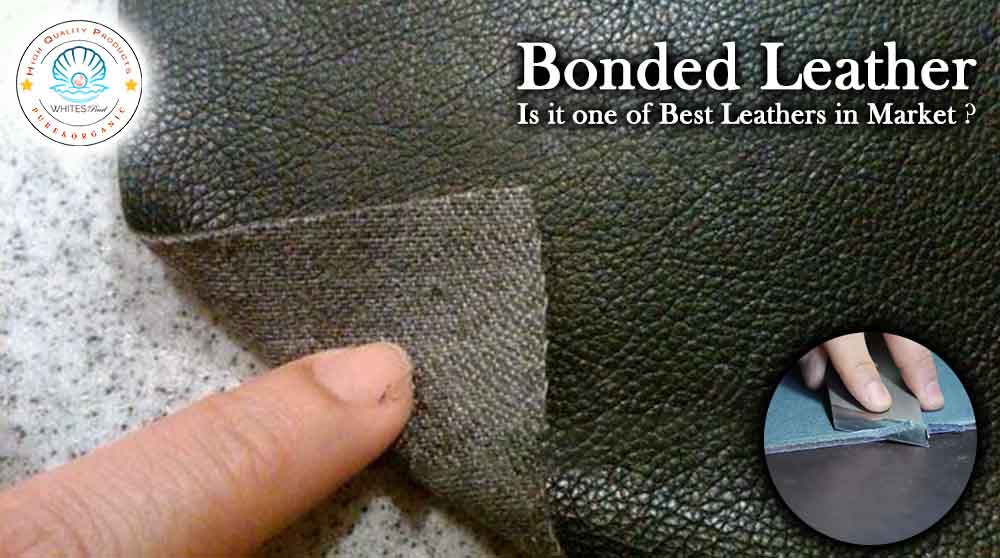

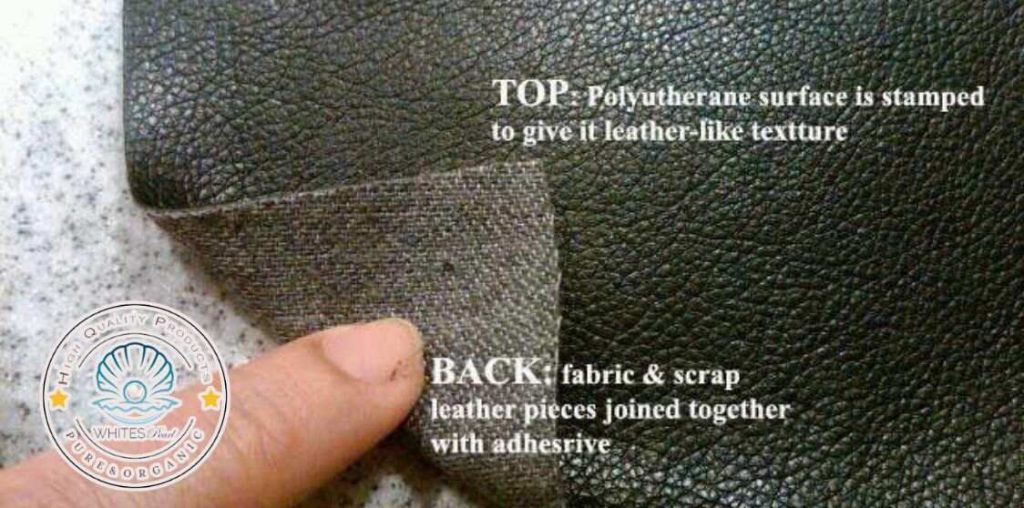

This leather is composed of scraps and fibers of leather that are left over after genuine leather is processed. These scraps and fibers and then bonded together via later or polyurethane on top of a fiber sheet to make bonded leather. Due to this process, waste is reduced as manufacturers use every bit and scrapes of original leather, however, in the mix the real leather content is minimal, about only 10% to 20%.

Even though bonded leather has the word leather incorporated in its name, it is a far cry from other types of leather. In this article, we will dive deep into the hows and whats of bonded leather so you can understand what this leather actually is and how it differs from other types of leather.

Bonded Leather

The Characteristics of Blended Leather

Bonded leather harbors distinct characteristics that set it apart from other types of leather. These characteristics become a part of the leather due to its unique material composition and production process. Given below are the characteristics of bonded leather:

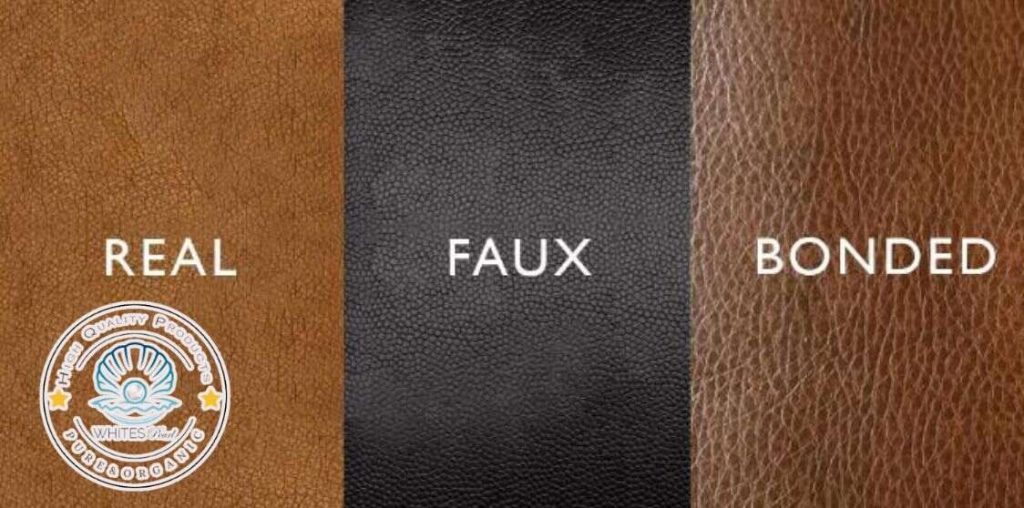

Texture and Appearance – To the untrained eye, bonded leather looks a lot like real, genuine leather. It is able to mimic the appearance of real leather because, during the manufacturing process, the manufacturer can imprint patterns on the bonded leather that resemble natural leather grain. However, once you feel both leather side by side you will notice a significant difference. Genuine leather harbors a unique texture and richness that bonded leather lacks. Bonded leather has a more plastic-like feel to it, lacking the suppleness and organic feel of real leather.

Durability – It is common knowledge that full grain and top grain leathers are the most durable of the bandh, however, bonded leather lacks their durability. Over time, reconstituted leather tends to crack, peel, and fade as synthetic materials are used in its manufacturing, and it is not 100% natural.

Consistency – Even though reconstituted leather lags behind in texture and durability, it makes up for it in its consistency. As this leather is man-made, it possesses the ability to be produced with a uniform texture and color, which can prove to be beneficial in the manufacturing of certain leather products.

Price – When it comes to price, bonded leather is a lot less expensive as compared to other types of leather. This reduction in price is due to the fact that its production and processing costs a lot less as compared to other grades of leather. Even though the lower cost might seem like an advantage at first, however, later proves to be a curse in disguise due to the reduced longevity and durability of bonded leather which can lead to replacement earlier than expected.

Composition of Blended Leather

Blended leather is a composite material that consists of varying percentages of scrapes of real leather as well as a binding agent, either latex or polyurethane. The exact composition of blended leather can vary from manufacturer to manufacturer; however, it falls typically within the ranges given below:

Leather Scarps – 10 Percent to 20 Percent

After the processing of real leather, some scrapes are left that are used in the manufacturing of bonded leather to prevent wastage. These scrapes are grounded into fine dust and are bonded with a binding agent. Due to these scrapes, the basic leather structure, and a small degree of strength are incorporated into the bonded leather. However, as these scrapes are subjected to shredding, they do not possess the strength and durability of full-grain leather.

Binding Agent – 80 Percent to Percent

Most commonly polyurethane is used as a binding agent in the manufacturing of bonded leather. It acts as a glue that holds together the pieces of leather. This binding agent forms the majority of the product, giving blended leather its flexibility as well as shape. Later on, in order to imitate the appearance of genuine leather, blended leather is subjected to embossing.

Characteristics of Material

The small amount (10% to 20%) of leather scrapes used in the manufacturing of blended leather contributes a light textural similarity to real leather as well as a faint natural leather scent. Both of these aspects make bonded leather look similar to real leather at first glance. The material that makes up more than half of bonded leather, about 80% to 90% is the polyurethane binder, or binder material.

As the binder material is plastic, bonded leather feels stickier and hotter in the summer season. Moreover, bonded leather is also prone to wear and tear, cracking, fading as well as peeling. Therefore, even though bonded leather is a low-cost substitute for real leather, its lack of durability and less desirable characteristics make it a less attractive option.

Process of Blended Leather Production

Blended leather, also known as blended leather or reconstituted leather is a lot different from traditional, full-grain, or top-grain leather. This is because it is a man-made product that utilizes leather scrapes. Given below is a step-by-step manufacturing process of:

Step 1: Collection of Scrapes – In the production of blended leather the first step is the gathering and collection of leather scrapes. These scrapes are those that are left over after larger leather products are subjected to the cutting process. These scrapes can come from a wide variety of sources, hence there can be significant variation in the quality of the collected scrapes. Sometimes, when manufacturing blended leather, manufacturers tend to add other fibrous materials in the mix as well.

Step 2: Pulverizing – Once the scrapes are collected, they are shredded or pulverized to convert them into smaller fibrous particles. The exact size of these particles can vary however, the end goal is to create a fine, uniform material that has a texture similar to paper pulp.

Step 3: Bonding – Once the leather scrapes are finely shredded, they are mixed with a binding agent like latex or polyurethane. These binding agents serve the purpose of glue, sticking the shredded pieces together to form a leather pulp. Sometimes manufacturers tend to mix this pulp with additional chemicals so as to enhance the durability of the final product and also aid in the binding process.

Step 4: Extrusion and Backing – The leather pulp produced in the previous step is spread on t a backing material that could be either paper, fiber cloth, or any other material that can seamlessly support the bonded leather as it forms. The extrusion process aids in the spreading of pulp on the backing material, resulting in large sheets of bonded leather material.

Step 5: Embossing – After the creation of the sheets, the texture of genuine leather grain is mimicked by embossing the sheets. During this process, heat and pressure are used, while plates and rollers, with leather-like texture engravings are used to emboss the bonded leather sheets.

Step 6: Coloring in finishing – The last step of manufacturing bonded leather involves the application of dyes and finishes. This step is conducted in order to give bonded leather the desired sheen and color. During this process, the bonded leather sheets go through several coating processes and each layer serves a specific purpose like enhancing texture, durability, color, resistance to sun and water damage, etc.

One thing that must be kept in mind is that even though scraps of real leather are used to manufacture bonded leather, it does not possess the same qualities as real leather. It is neither durable nor does it have a luxury feel. It is however low-cost leather, but due to its brittle nature, it tends to wear out quickly in about 2 to 5 years, while real leather can withstand the trials of time, lasting for decades on end.

Uses of Blended Leather

Due to its low cost and uniform appearance, many industries tend to use bonded leather to fill in for real leather. Given below are some common uses of bonded leather:

Furniture – As bonded leather possesses a consistent appearance and is cost-effective, it is in high demand for manufacturing budget-friendly furniture items such as chairs, sofas, and ottomans. The bonded leather effortlessly provides a “real leather-like look” at a fraction of the price of real leather and hence it is coveted by many manufacturers and shoppers.

Small Goods and Accessories – To keep the cost low, bonded leather is used to make smack sale items like belts, keychains, wallets, etc. However, as these items suffer through frequent usage, they tend to deteriorate quite quickly as bonded leather is not durable enough.

Bookbinding – A frequent use of bonded leather is seen in the binding of books, photo albums, and diaries. As these items suffer through less wear and tear as compared to wallets, and belts, the less durability, and longevity of bonded leather is not an issue.

Automotive Upholstery – To keep the cost of leather car interiors low, many car manufacturers opt for bonded leather automotive upholstery. However, bonded leather cars or automotive interiors are not as ideal as other leathers because they tend to peel and crack very quickly, forcing to user to replace them after a year or two.

Why Does Blended Leather Lack Durability?

As durability depends on structure, the structure of bonded leather is less stable and resilient, decreasing its durability. Given below are some key reasons, why bonded leather is not as durable as other types of leather:

Composite Material – Blended leather is known as a campsite material, meaning that it consists of multiple layers. As time progresses, these layers tend to separate, especially if they are subjected to harmful conditions and frequent usage. This phenomenon is called delamination and is a common issue when it comes to products made up of bonded leather.

Quality of Raw Materials – Blended leather is made when ground-up scrapes are bound together with the help of a binding. Agents. These scraps are different in quality which can have an impact on the durability of the end product. Moreover, as these scrapes are grounded into small particles, they lack the natural fibrous structure that is posed by full-grain leather. This fibrous structure is responsible for the longevity and strength of leather.

Less Wear and Tear Resistance – It is common knowledge that full-grain leather develops a patina over time and becomes more beautiful and elegant as time progresses. However, that is not the case with bonded leather. Blended leather does not age well and harbors less resistance to wear and tear. Over time it tends to crack and peel with usage.

Binding Agents – In order to hold the small leather particles together, binding agents such as latex and polyurethane are required. However, as time progresses these agents become brittle and break down which leads to cracking and peeling of blended leather.

Sensitivity to Environmental Conditions – Unlike full-grain leather, blended leather is more sensitive to environmental conditions. In conditions of high humidity, bonded leather reacts adversely, leading to swelling and warping. Moreover, when the conditions are dry, bonded leather can dry out, resulting in cracks and peels.

Production Process – When bonded leather is being manufactured, it is exposed to high pressure and heat, which reduces its strength. Moreover, during manufacturing, some harsh chemicals are also used that result in the degradation of leather over time.

Difference Between Blended Leather and Full Grain Leather

| Full-Grain Leather | Bonded Leather |

| Quality and Durability – As full-grain leather is composed of the uppermost layer of hide, it harbors the natural marking as well as the grain, which gives it a unique, elegant look. This leather also possesses high resistance to wear and tear and ages beautifully with time. | Quality and Durability – Blended leather is composed of leather scrapes that are ground together. Due to the grounding process the natural fibrous structure is lost which also results in a decrease in durability as well as resistance to wear and tear. Bonded leather also does not age well and suffers from cracks and peels over time. |

| Feel and Appearance – Full-grain leather harbors an elegant appearance with a rich, organic feel. | Feel and Appearance – Blended leather, even though looks like real leather at full glance, it cannot mimic the rich feel of real leather. |

| Sustainability – During the manufacturing process, full-grain leather is mostly vegetable-tanned which makes it more environmentally friendly. | Sustainability – Blended leather is not environmentally friendly as its manufacturing involves synthetic binding agents |

| Price and Value – As full-grain leather s top-notch, high quality leather, it carries a hefty price tag. However, it is good investment as full-grain leather can last for decades if taken care of properly | Price and Value – On the other hand, bonded leather is a lot cheaper as compared to full-grain leather however it lacks quality and tends to lose its allure quickly due to its less durability and longevity. Bonded leather can lats for a maximum of 2 to 5 years after which, replacing it becomes a necessity. |

Spotting the Difference Between Real and Blended Leather

When you are purchasing leather, keep the following points in mind to distinguish between real and bonded leather:

Labeling – The law requires brands to label their products accurately. Therefore, when shopping for leather, keep in mind that products labeled “Full Grain” “Genuine Leather” or “Top Grain Leather” are real leather products. On the other hand, products labeled “Reconstituted Leather” “Leather Blend” or “Bonded Leather” are made from bonded leather.

Price – The products that are made with blended leather are cheaper than the items made from full-grain or top-grain leather. In case you come across a leather product, that advertises itself as real leather, however its price is too low to be true, there is a possibility that that product is made of bonded leather.

Smell and Texture – Real leather has a distinct feel and smell that allows one to differentiate it from bonded leather. Bonded leather can even though mimics the appearance of real leather, it fails to mimic its feel and smell. Bonded leather feels synthetic and does not carry the unique leathery smell.

Uniformity – As bonded leather lacks all the imperfections harbored by full-grain leather it can have a consistent texture and a uniform look. If you come across a leather product that doesn’t carry natural grain variation or markings, chances are that it is bonded leather.

Durability – Over time as full-grain leather becomes more elegant and develops a beautiful patina, bonded leather tends to peel and crack due to less durability.

How to Prevent the Peeling of Blended Leather

Use it Gently – Gentle use is the key to making your bonded leather last long. As bonded leather possesses less durability, it is of vital importance to treat it gently to avoid peeling and cracks.

Clean Regularly – In order to preserve the integrity and appearance of bonded leather, make sure to clean it regularly. Make a habit of dusting off, and cleaning the surface of blended leather gently with either a mild soap solution or a leather cleaner.

Conditioner – To prevent bonded leather from drying out and maintain its flexibility, use a leather conditioner that is designed specifically for blended leather like Whites Pearl Leather Conditioner. However, keep in mind to use conditioner sparingly as over-conditioning can also cause harm to leather.

Avoid Exposure to Heat and Sunlight – Keep your bonded leather items away from heat and sunlight as they can result in drying which causes cracks and peeling.

Use Covers – To protect blended leather from wear and tear and harsh atmospheric elements, consider covering it.

Also Read

Top-Grain Leather vs Full-Grain Leather: Which One is the Better Option?

Ultimate Guide to Leather Care

Ultimate Guide to 5 Types of Leather