There are different forms and types of leather. Two names that are normally thrown around the leather industry include full-grain leather and top-grain leather. Full-grain leather is the highest quality of leather and second, to it lies top-grain leather. When one hears of these types and forms, a wave of questions arises in the mind about their durability, quality, and position in the hierarchy of leather types. In this article, we will delve deep into the definition of top-grain leather and explore its properties, production as well as characteristics. So, hang on to your leathers, as we embark on an enthralling journey of exploration and understanding.

Top-Grain leather

What is Top-Grain Leather? Is It Real or Not

Top-grain leather is the highest quality of leather, second to full-grain leather. This leather is made out of the outer layer of the hide and unlike full-grain leather, which bears marks and scratches, dictating the story of the animal it is derived from, top-grain leather is void of scratches and other imperfections. This is because top-grain leather is subjected to sanding and buffing that removes natural imperfections as well as the unique patterns of hide. Once sanding is done, a new finish coat is applied to the leather to give it a uniform look. This process gives the leather a smooth and consistent look, void of any scars, blemishes, and imperfections.

Coming towards the question of whether top grain leather is real leather or not, top grain is indeed very much real leather. It is important to take into consideration that, not all leathers are created the same and pass through different processes that give them their distinct properties and personalities. Classification of leather is based on the part of animal hide used to create it, as well as the process of production.

Navigating the Place of Top Grain Leather in the Leather Hierarchy

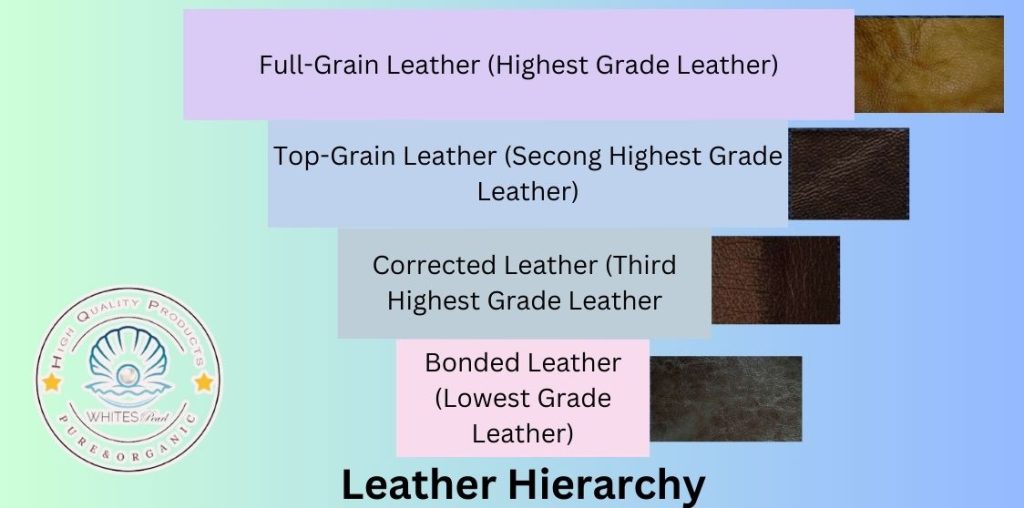

Leather is a material that is as old as civilization itself and for eons has been associated with durability, opulence, and elegance. We all have a general idea that leather comes in different forms and not every form is created equally. But did you know that there are four primary grades of leather? The highest quality, crème de la crème of leather is full grain leather that is derived from the topmost layer of the hide.

Then in second place comes top-grain leather that is derived from the second layer of hide and is subjected to the process of sanding or buffing to remove imperfections. Genuine leather or corrected leather comes in third place and is derived from the layers of hide that are left after the top is split off to make higher grades of leather. At the end of the hierarchy resides bonded leather that is made from leather scarps that are combined via a filler.

Step By Step Making of Top Grain Leather

Top grain leather, which is the second highest grade of leather, starts its journey as full grain leather. In the beginning top grain bears the natural marks texture, and imperfections of the skin of the animal it is derived from. However, as it goes through the transformation process, little by little Top Grain starts establishing its own personality and characteristics. Let’s take a look at the step-by-step manufacturing process of top-grain leather:

Selection of Hide – The first step in the manufacturing of top grain leather is the selection of high-quality hide. These hides mostly come from cow hides; however, the hides of other animals can also be used.

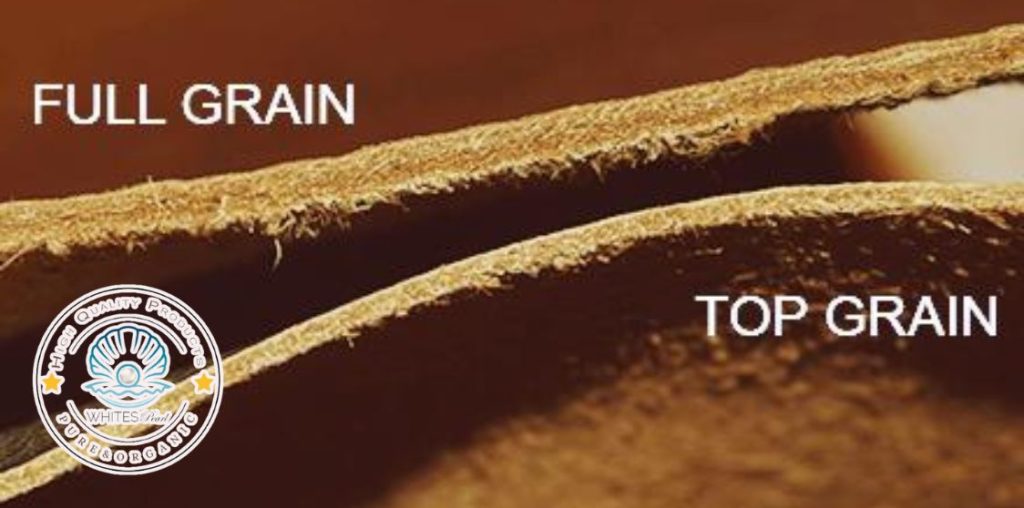

Splitting – Once the hide is selected, the next step in the manufacturing of top-grain leather is splitting. During this process, the hide is sliced into two layers horizontally, the top layer includes the hair and epidermis, and the bottom layer that is also regarded as corium. The top-grain is created from the top layer which is the strongest and the most durable part of hide.

Buffing and Sanding – Once splitting is done, the top layer goes through sanding or buffing. This process removes natural imperfections like insect bites, wrinkles, and scars. The end product of this process is a smooth and even hide.

Pigmentation and Finishing – Once the leather is smooth and even, it is treated with pigments that help create a uniform color. The pigmentation process is sometimes followed by the process of finishing during which a protective coating is applied on the surface of leather that makes it more resistant to fading and stains.

Graining – In the end, an artificial grain pattern is embossed on top-grain leather this gives the leather a signature and authentic look.

Characteristics

Texture – Due to the sanding and buffing process that top-grain leather undergoes during the process of manufacturing, its surface is smoother and harbors a consistent texture. Top-grain leather is also less porous, has an even and uniform surface, and is void of imperfections.

Durability – Top-grain leather is durable and strong, albeit not as durable as full-grain leather as it lacks the natural toughness possessed by full-grain leather. As a result of sanding and buffing, some of the natural resilience and fiber strength of leather is lost. However, top-grain leather is still durable and is ideal for items that require the ultimate balance of opulence and endurance.

Flexibility – Top grain leather is a lot more flexible than full grain leather as the toughest fibers in the hide are removed due to sanding and buffing. Due to its flexibility, top-grain leather is easier to work with and can be used in furniture upholstery or products that require more structure and shape.

Aging – The aging process of top-grain leather is less pronounced and unlike full-grain leather, top-grain does not develop a patina with time. It does not develop a beautiful patina due to the protective coating and treatments that provide resistance against stains and damage.

Maintenance – Top-grain leather is much easier to clean and maintain as it harbors a porous nature and is covered in protective coatings. Due to the protective coating, top-grain leather is more resistant to stains and damage.

Application

Furniture – The furniture industry is the most avid user of top-grain leather. In the furniture industry, Top-grain is used for manufacturing armchairs, ottomans, and sofas. Due to the smooth and uniform texture of leather, it offers comfort and a high aesthetic. Also, as top-grain leather is resistant to stains and spills, it is ideal for everyday use.

Wallets and Handbags – In the fashion industry, top-grain leather is used in the production of, wallets, handbags as well as other accessories. The flexibility, durability, and softness of top-grain leather make it ideal for high-end products that want to strike a balance between luxury, and function.

Clothing – Due to its comfort and pliability, top-grain leather is used to make jackets, pants, and other leather clothing. As top grain leather surface is treated with protective costings, it makes it resistant to the elements of the atmosphere, making top grain leather a good choice for the production of outerwear.

Footwear – Due to its durability, top-grain leather is a popular material for creating high-end shoes that range from casual shoes to dress shoes. Moreover, as top-grain leather is also adaptable it can be dyed in various colors and molded in numerous shapes to suit the taste of different kinds of buyers.

Bookbinding – This usage of top-grain leather is less common in today’s era. However, even today, top-grain leather is used for binding antique and luxury books. Due to its durability, the pages of the book remain protected, while the smooth surface of the leather adds to the aesthetic appeal of the book.

Automotive Upholstery – In the automotive industry, top-grain leather reigns supreme. It is used for making car interiors, due to its durability and appeal.

Care and Maintenance

Regular Cleaning – Even though the top grain is a durable leather; it still demands care and maintenance. To clean your leather of dust and grime, opt for a top-notch cleaner, apply a bit of cleaner on a lint-free cloth, and wipe the surface of the leather. Leave the leather to dry naturally for almost 24 hours.

Regular Conditioning – To maintain the resistance properties and suppleness of leather, make sure to condition it every 6 months or so. Take a small amount of Whites Pearl Leather Conditioner on a soft cloth and massage the product on the surface of the leather gently. Once done, leave the leather to dry for 24 hours.

Protect from Heat and Direct Sunlight – Heat and sunlight are to leather-like kryptonite is to Superman. So, make sure to keep your leather away from sunlight and heat sources like heaters, radiators, etc. Heat and sunlight can cause the natural oils in leather to evaporate, resulting in fading and drying.

Store in a Cool, Dry Place – Try to store your leather items in a cool and dry place. Avoid humid places at all costs, because humidity can lead to molds and mildew.

Keep Away from Harsh Chemicals – Make sure to keep your leather away from harsh cleaners and chemicals as they do more harm than good and result in the deterioration of leather.

Also Read

Top-Grain Leather vs Full-Grain Leather: Which One is the Better Option?

Ultimate Guide to Leather Care

Ultimate Guide to 5 Types of Leather